Precision Electronics

HANDING OPTICAL

With the development of science and technology, today's manufacturing industry has higher and higher requirements for the measurement accuracy of various components, so the requirements for the visual measuring machine, a measuring instrument, are becoming more and more demanding. It is the product of the perfect combination of traditional optical projection and computer, which has obvious advantages over traditional measurement technology.

Traction Battery

HANDING OPTICAL

The traction battery system is a system that combines the hardware ontology and the control system very closely. Its testing can be roughly divided into two parts: battery pack body (Pack) testing and battery management system (BMS) testing.

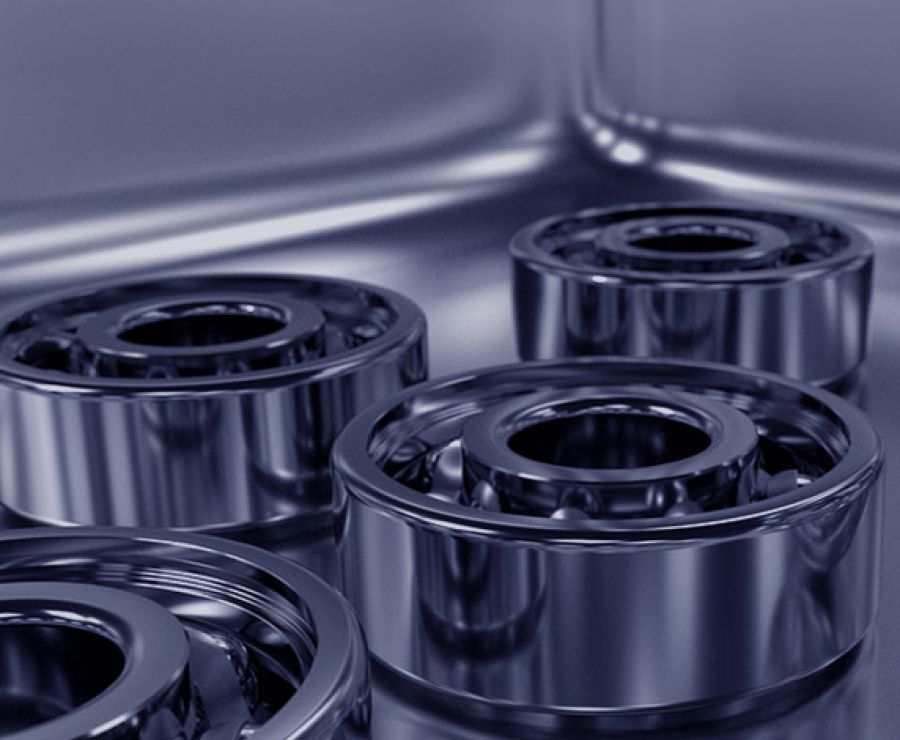

Precision Hardware

HANDING OPTICAL

The vision measuring machines are mainly used for internal inspection, positioning, evaluation and diagnosis of workpieces. It mainly inspects some defects inside the workpiece, such as size, cracks, pores, inclusions, welds, etc. It is used in a wide range of industries, but the development in the precision hardware industry is more significant.

Medical Instruments

HANDING OPTICAL

Medical devices must have strict quality assurance, and no mistakes can be made, and product quality monitoring and testing largely rely on precision measuring instruments. There are many measuring instruments used to detect medical devices. According to the characteristics of the products, there are several commonly used measuring instruments, such as video measuring machines and instant vision measuring machines.

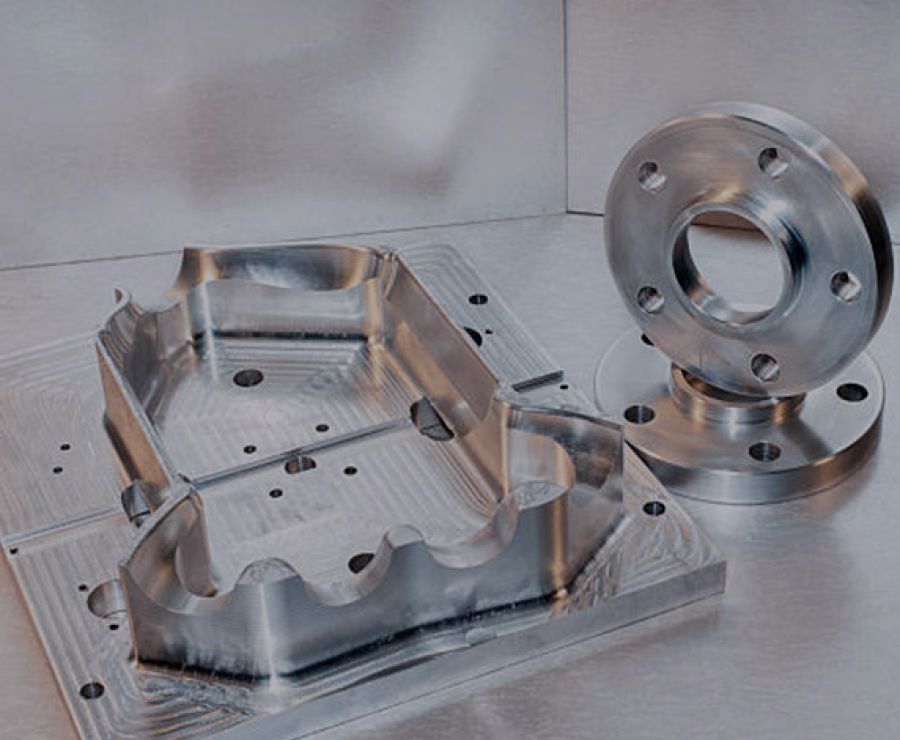

Mould

HANDING OPTICAL

In mold processing, product quality is the life of an enterprise. The quality of mold products needs to be guaranteed, and manufacturers also need to use this to measure whether the products are qualified. Therefore, choosing the right precision measuring instrument for product testing is a very important part, and it is also related to the quality of the entire product.

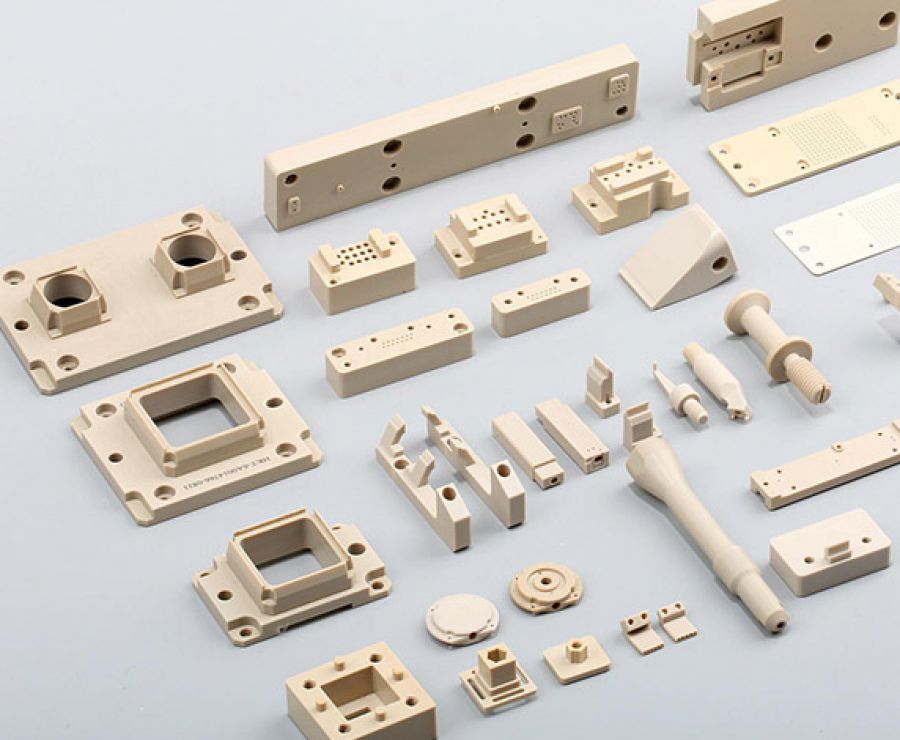

Plastics

HANDING OPTICAL

The video measuring machine is a kind of precision measuring equipment, which is used in many plastic processing industries. It can clearly and accurately measure the size and tolerance range of plastic products, and can generate 2D or 3D engineering drawings from the measured data through a computer, which can greatly reduce labor costs.