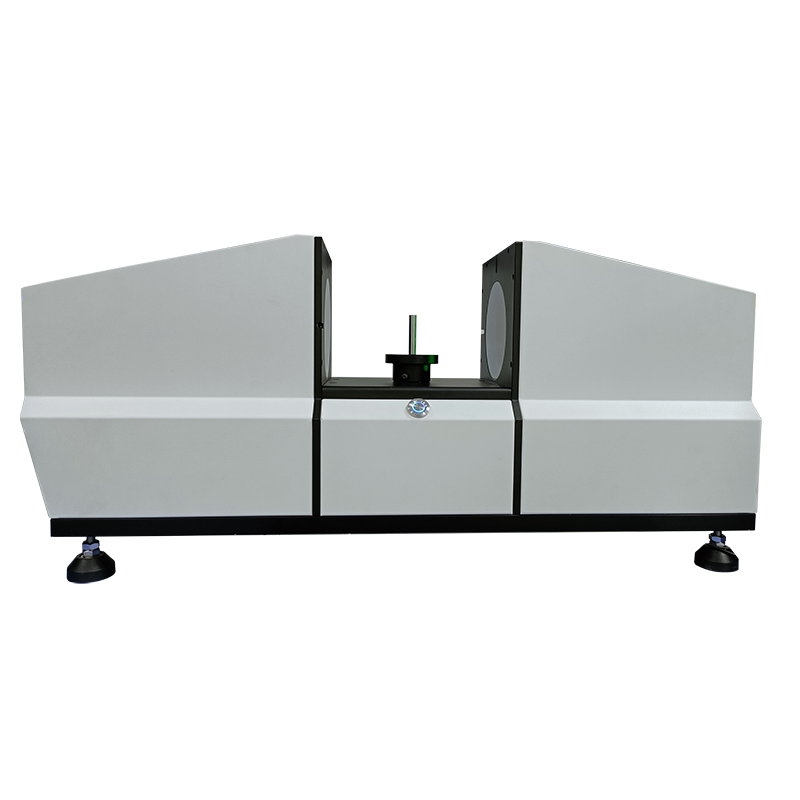

Semi-automatic PPG Thickness Gauge – Handing

Semi-automatic PPG Thickness Gauge – Handing Detail:

The PPG is suitable for measuring the thickness of lithium batteries, as well as measuring other non-battery thin products. It uses stepper motors and sensors to drive, which makes the measurement more accurate.

2.1 Turn on the computer;

2.2 Power on the instrument;

2.3 Open the software;

2.4 Initialize the instrument and return to the origin;

2.5 Put the standard gauge block into the equipment for calibration

2.6 Start measuring.

3.1.Sensor: Open grating encoder.

3.2.Coating: Stoving varnish.

3.3.Material of parts: steel, grade 00 jinan blue marble.

3.4.Cover material: Steel and aluminum.

|

S/N |

Item |

Configration |

|

1 |

Effective test area |

L200mm × W150mm |

|

2 |

Thickness range |

0-30mm |

|

3 |

Working distance |

≥50mm |

|

4 |

Reading resolution |

0.0005mm |

|

5 |

Flatness of marble |

0.003mm |

|

6 |

Measurement error of one position |

Put a 5mm standard gauge block between the upper and lower pressure plates, repeat the test 10 times at the same position, and its fluctuation range is less than or equal to 0.003mm. |

|

7 |

Comprehensive measurement error |

A 5mm standard gauge block is placed between the upper and lower pressure plates, and the 9 points evenly distributed in the pressure plate are measured. The fluctuation range of the measured value of each test point minus the standard value is less than or equal to 0.01mm. |

|

8 |

Test pressure range |

500-2000g |

|

9 |

Pressure method |

Use weights to pressurize |

|

10 |

Work beat |

9 seconds |

|

11 |

GR&R |

<10% |

|

12 |

Transfer method |

Linear guide, screw, stepper motor |

|

13 |

Power |

12V/24v |

|

14 |

Operating environment |

Temperature:23℃±2℃ Humidity:30~80% |

|

Vibration:<0.002mm/s,<15Hz |

||

|

15 |

Weigh |

45kg |

|

16 |

***Other specifications of the machine can be customized. |

|

Are your products traceable? If so, how is it implemented?

Each of our equipment has the following information when it leaves the factory: production number, production date, inspector and other traceability information.

Who are your company’s suppliers?

Hiwin, TBI, KEYENCE, Renishaw, Panasonic, Hikvision, etc. are all our accessories suppliers.

How long is the service life of your products?

Our equipment has an average lifespan of 8-10 years.

Product detail pictures:

Related Product Guide:

We support our consumers with ideal good quality merchandise and large level provider. Becoming the specialist manufacturer in this sector, we have attained wealthy practical encounter in producing and managing for Semi-automatic PPG Thickness Gauge – Handing , The product will supply to all over the world, such as: Monaco, Hongkong, Libya, Our items have national accreditation requirements for qualified, high quality products, affordable value, was welcomed by people today all over the world. Our goods will continue to enhance within the order and look forward to cooperation with you, Should any of these products be of interest to you, please letus know. We are going to be content to offer you a quotation up on receipt of your detailed needs.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

-

Top