Professional Design Automatic Vision Measuring Systems With Laser & Probe - Spliced instant vision measuring machine – Handing

Professional Design Automatic Vision Measuring Systems With Laser & Probe - Spliced instant vision measuring machine – Handing Detail:

The stant vision measuring machine has the characteristics of rapid measurement and high precision, it perfectly combines far-heart imaging with intelligent image processing software,and will be the tedious measurement task, become extremely simple.

You simply place the workpiece in the effective measurement area, which instantly completes all two-dimensional size measurements.

Instant vision measuring machine is widely used in machinery, electronics, mold, injection molding, hardware, rubber, low-voltage electrical appliances, magnetic materials, precision stamping, connectors, connectors, terminals, mobile phones, home appliances, printed circuit boards, medical devices, clocks, knives and other small size of products and parts of the batch rapid measurement.

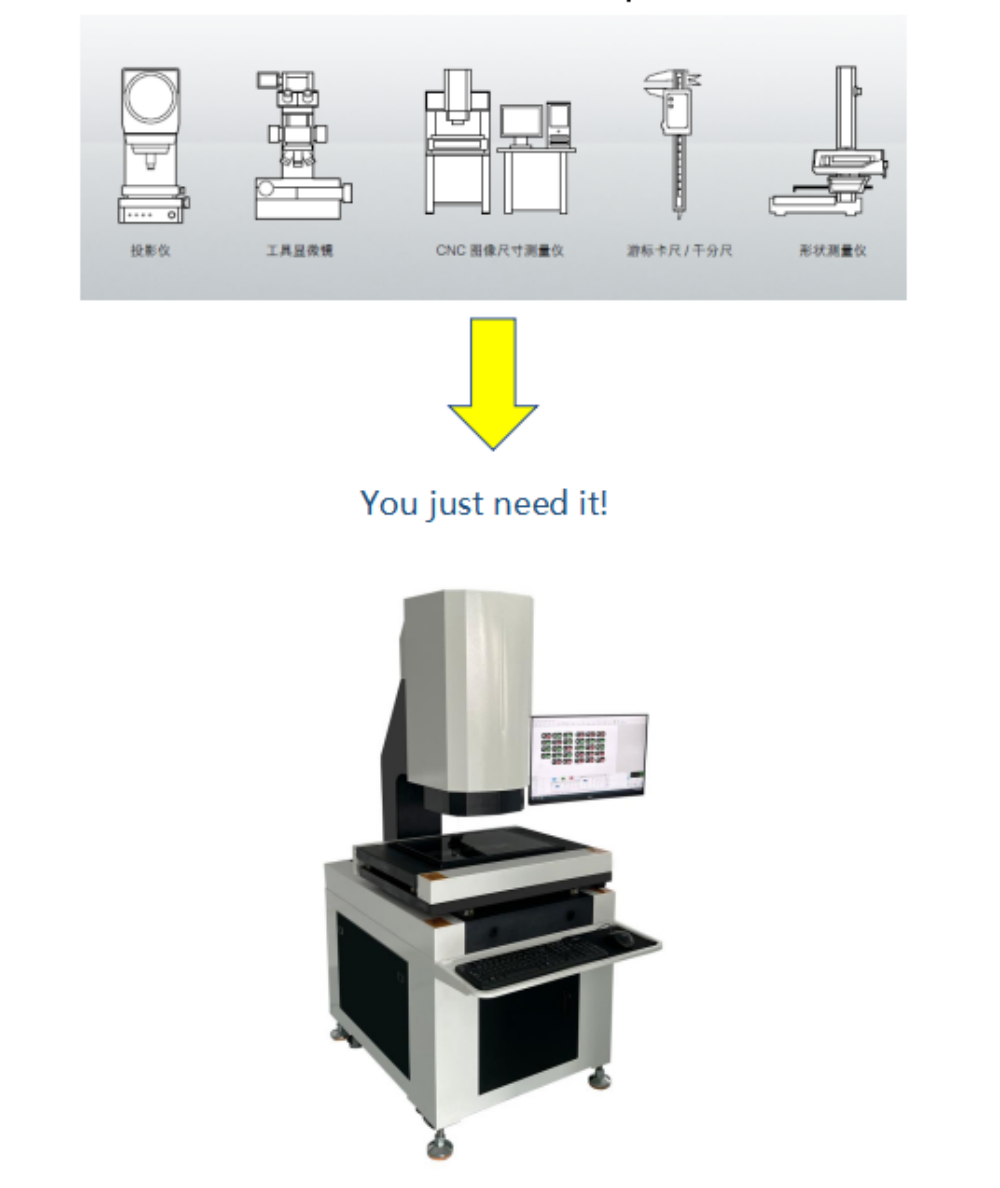

1.Break the routine of size measurement.

High resolution digital Camera. The instrument uses a 20-megapixel high-resolution digital camera.

Automatically identifies artifacts without positioning.

Efficient batch measurement.

Within the measurement range, more than 20,000 sizes can be measured at once, and the measurement time of 100 sizes is less than 1 second, which greatly shortens the measurement time and improves the measurement efficiency.

Multiple workpieces are arbitrarily placed arbitrarily, automatic identification, batch measurement.

Fully independent development, simple software interface, powerful function, easy to learn; adopt the distortion correction technology to ensure stable and accurate measurement results of the independently developed image splicing technology, ensure the splicing error is less than 0.003mm.

(Special software features acceptable to customization)

user program:

1.Automatic matching of artifacts, arbitrary placement, one-click measurement. Automatically search for matches and calls up user programs. Box box to establish matching, multiple location box combination to establish matching, establish matching with measurement elements, can import CAD to establish matching. Program group can be established to realize multiple flip measurement of workpiece.

2. Comprehensive measurement elements:

Point, highest point, line, highest line, circle (center coordinate, radius, diameter, true circle, circumference, area, maximum radius, minimum radius), arc, rectangle (, center coordinate, length, width, circumference, area), oval (center coordinate, long axis, short axis, circumference, area), key slot (, center coordinate, length, width, circumference, area), import CAD profile scanning alignment, contour PV, area contrast, cylinder diameter, seal ring (maximum radius, minimum radius, thickness), measurement results (maximum, minimum, mean, sum), QR code identification, barcode identification.

3.tagging:

Distance, X distance, Y distance, Radius, Diameter, Angle.

4.Shape error assessment:

Straightness, roundness.

5.Position error assessment:

Parallel degree, verticality degree, symmetry degree, concentricity degree, position degree.

6. transfer of axes

The Cartesian coordinates (X, Y) and polar coordinates (R, θ) can be easily selected. Basic units mm, inch, mil of measured values can be converted immediately. Coordinate translation, coordinate rotation, establish the workpiece coordinate system.

7. Measure the data

You can customize the EXCEL templates and specify the output cells. The software comes with a CPK template, which can calculate Mean, Maximum, Minimum, Cp, Cpkl, Cpku, and Cpk.

8.other

1. Software language: optional in multiple languages, open in language package, and can define translation and modification.

2. Image and drawing area sharing, what you see is what you get, can be customized: color, line width, font size, background color.

3. Focus assistance and light assistance functions to reduce human error.

4. Qualified / unqualified (OK / NG), and alarm prompt, can voice output: OK, NG.

5. The profile can be quickly scanned and exported to the CAD.

6. Optional IO card, external trigger measurement and OK NG signal output.

9. SPC :

Including: histogram, Cpk trend diagram, X control diagram, X b ar-R control diagram, Xmedian-R control diagram, X-Rs control diagram.

1. Easy operation and high efficiency

Improve operation efficiency, reduce labor cost, and avoid human error

Reduce the sample fixation, placement, calibration, focus, dimming, motion control, batch automatic measurement within the field of vision to improve the measurement efficiency.

2. Simple operation training, low use threshold, high test efficiency, which can save labor cost

|

prime cost |

Other measuring instruments |

One-key meter |

|

Save training costs |

It takes quite a long time to learn how to operate a meter; | Only one click (3-15 seconds to measure all sizes of the piece),Anyone can measure that,simplicity of operator; |

| Worried about the loss of skilled testing personnel, resulting in a “disconnect” phenomenon; | ||

|

Reduce the cost of use |

Limited to professional and skilled testing personnel, with high salary requirements (6,000 yuan / month); | Anyone can operate, general workers can meet the requirements (2500 yuan / month); |

|

Test efficiency cost |

The measurement is required to move the workbench to pick up the feature size, and the required time increases with the number of key feature sizes. A production workshop needs 5 to 10 machines with at least 1 to 2 skilled operators each; accumulate 2,000 operating hours per year | No need to move the workbench, fixed sample, repeated focus, instantly measure all the dimensions within the field of vision, a flash meter, a general worker can be; |

3. Measurement error is small. Avoid human error factors such as operation mode, sample placement and measurement order, and effectively eliminate the measurement error caused by man

|

Artificial error element |

Other measuring instruments |

One-key meter |

|

Measurement method |

Tsters are not familiar with software and machines, resulting in measurement errors | Automatic memory and storage measurement mode, point position, automatically adjust the test direction, and automatic execution, effectively eliminate human error |

| Test ester mentality changes, easy to cause measurement accuracy and stability deviation | Automatic and mechanized measurement to eliminate human error | |

| Short working distance and depth of field, requiring repeated autofocus, there is the possibility of misjudgment and mechanical error | High depth of field bilateral distant heart lenses, allowing the sample to existCertain height difference, without repeated focus | |

| Different tester cause deviation in measurement data due to differences in operation habits, focus clarity, point taking method, lighting light intensity and other aspects | Memory and automatically perform the same measurement mode, point-taking mode, optical illumination intensity, etc | |

|

Sample placement |

The direction | No fixtures, products can be placed at will |

| The displacement of the fixture and the movement of the point deviate the coordinate origin | The software automatically adjusts the sample position and direction for accurate measurement | |

| Take the point position, test the element order disorder | Automatic, mechanized measurement |

|

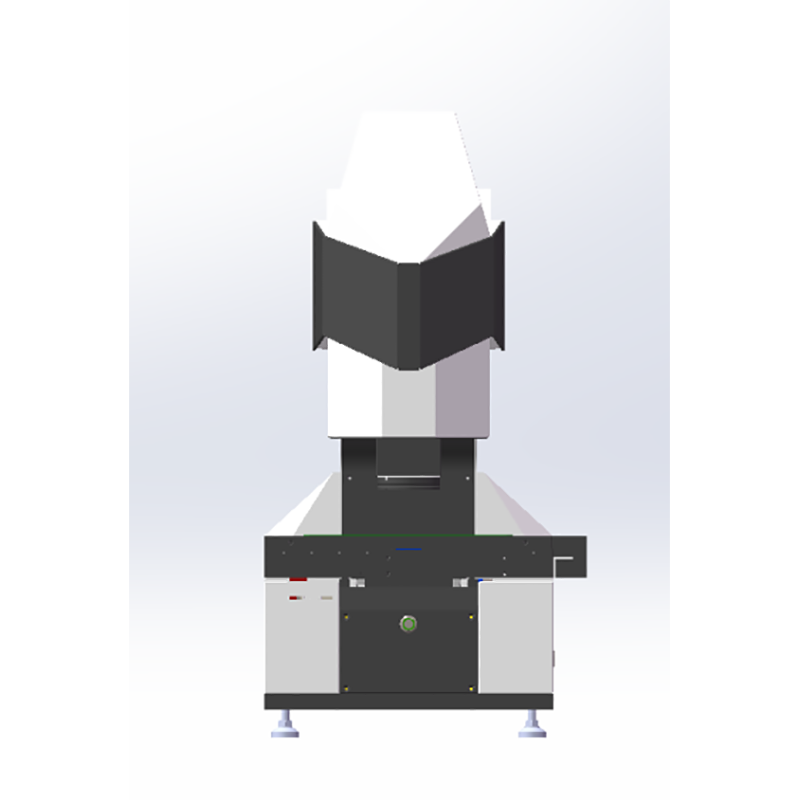

model |

IVM542 |

|

XY-axis measurement range (mm) |

500×400×200 |

|

Single visual field measurement range (mm) |

86×57 |

|

external dimension (mm) |

1353×886×1707 |

|

Instrument placement size (mm) |

2200×1900×2000 |

|

weight (kg) |

320 |

|

bearing (kg) |

20 |

|

imaging sensor |

The 20 MP Industrial Camera |

|

camera lens |

Double far-heart optical lens |

|

multiplying power |

0.151X |

|

certainty of measurement (μm) |

± (3.0 + L / 200) * with standard block as tested |

|

Minimum display unit (mm) |

0.0001 |

|

depth of field (mm) |

8 |

|

Z-axis operating distance (mm) |

150mm |

|

illuminant |

Level 1000 program light source.Contour light: Far-center parallel light sourceSurface light: Coaxial light |

|

image processing |

Advanced image analysis method, 256 gray scale level, 20:1 subpixel processing technology |

|

software |

i -VISION |

|

work environment |

Temperature: 22℃± 3℃ Humidity: 50~70% |

| Vibration: <0.002 mm/s, <15Hz | |

|

source |

220V/50Hz |

Optional:

①Software customization

②Optional 29 million or 43 million cameras are available

③Optional laser measurements of height dimensions

Huawei, Lens, TPK, Samsung, Foxconn, Huia, Flextronics, BYD, Mullinsen, etc.

Product detail pictures:

Related Product Guide:

We've one of advanced generation tools, experienced and qualified engineers and workers, recognized good quality manage systems and a friendly skilled product sales workforce pre/after-sales support for Professional Design Automatic Vision Measuring Systems With Laser & Probe - Spliced instant vision measuring machine – Handing , The product will supply to all over the world, such as: Albania, Germany, Sacramento, With the intensified strength and more reliable credit, we are here to serve our customers by providing the high quality and service, and we sincerely appreciate your support. We will endeavor to maintain our great reputation as high quality products supplier in the world. If you have any questions or comments, please contact with us freely.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

-

Top