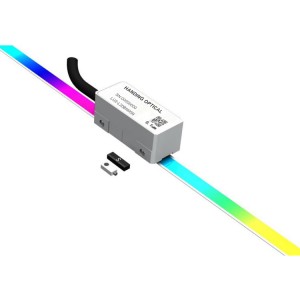

JCX22 high-precision optical encoders

1. Product Overview

The steel belt grating is a precision measurement tool designed for linear and angular positioning applications in various industries. It combines robust construction with advanced optical technology for high precision and long-term reliability.

2. Key Features

High measurement accuracy with excellent repeatability.

Durable and resistant to harsh industrial environments.

Supports integration with automation and control systems.

Low-maintenance design for cost-effectiveness

3. Technical Specifications

Material: High-strength stainless steel.

Accuracy Grade: ±3 µm/m or ±5 µm/m (depending on model).

Maximum Length: Up to 50 meters (customizable based on requirements).

Width: 10 mm to 20 mm (specific models may vary).

Resolution: Compatible with high-precision optical sensors (up to 0.01 µm depending on system configuration).

Operating Temperature Range: -10°C to 50°C.

Storage Temperature Range: -20°C to 70°C.

Thermal Expansion Coefficient: 10.5 × 10⁻⁶ /°C.

Clock frequency: 20MHz

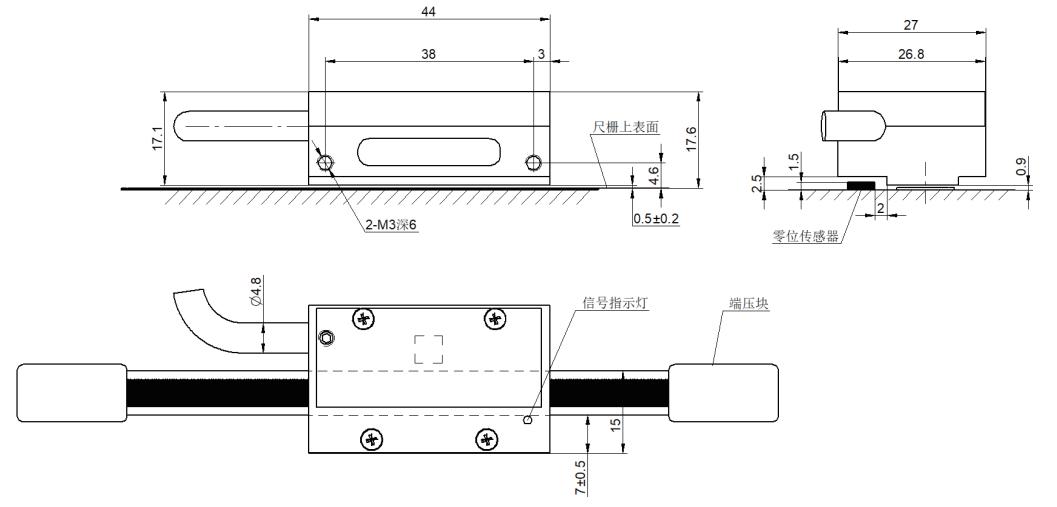

4. Dimension Drawing

The steel belt grating's dimensions are detailed in the technical drawing, which specifies the following:

Grating Body: Length varies based on model (up to 50 meters); width is between 10 mm and 20 mm.

Mounting Hole Positions: Precisely aligned for secure and stable installation.

Thickness: Typically 0.2 mm to 0.3 mm, depending on model.

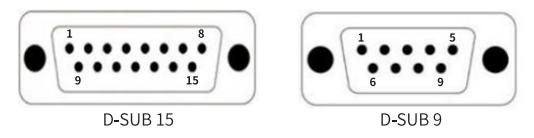

5. D-SUB Connector Details

Pin Configuration:

Pin 1: Power Supply (+5V)

Pin 2: Ground (GND)

Pin 3: Signal A

Pin 4: Signal B

Pin 5: Index Pulse (Z Signal)

Pin 6–9: Reserved for custom configurations.

Connector Type: 9-pin D-SUB, male or female depending on the system design.

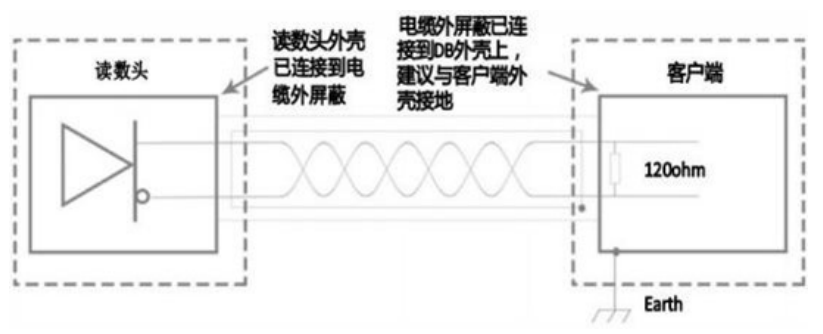

6. Electrical Wiring Diagram

The electrical wiring diagram outlines the connections between the steel belt grating and the system controller:

Power Supply: Connect the +5V and GND lines to a regulated power source.

Signal Lines: Signal A, Signal B, and Index Pulse should be connected to the corresponding inputs on the control unit.

Shielding: Ensure proper grounding of the cable shield to prevent electromagnetic interference.

7. Installation Guidelines

*Ensure the installation surface is clean, flat, and free of debris.

*Use the recommended mounting brackets and alignment tools for precise positioning.

*Align the grating with the measurement axis, ensuring no twists or bends.

*Avoid exposure to contaminants like oil or water during installation.

8. Operation Instructions

*Confirm proper alignment and calibration before use.

*Avoid applying excessive force to the grating during operation.

*Monitor for any deviation in readings and recalibrate as needed.

9. Maintenance and Troubleshooting

Maintenance:

*Clean the grating surface using a soft, lint-free cloth and alcohol-based cleaner.

*Periodically check for physical damage or misalignment.

*Tighten loose screws or replace worn-out components.

Troubleshooting:

*For inconsistent measurements, check alignment and recalibrate.

*Ensure optical sensors are free of obstructions or contamination.

*Contact technical support if problems persist.

10. Applications

The steel belt grating is commonly used in:

*CNC machining and automation.

*Robotic positioning systems.

*Precision metrology instruments.

*Industrial manufacturing processes.

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

-

Top