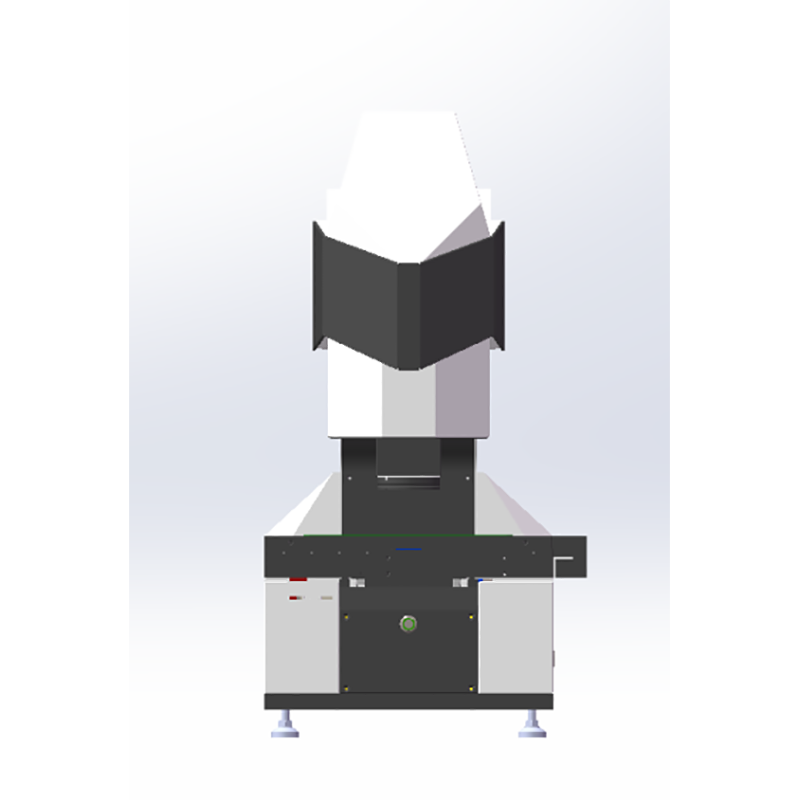

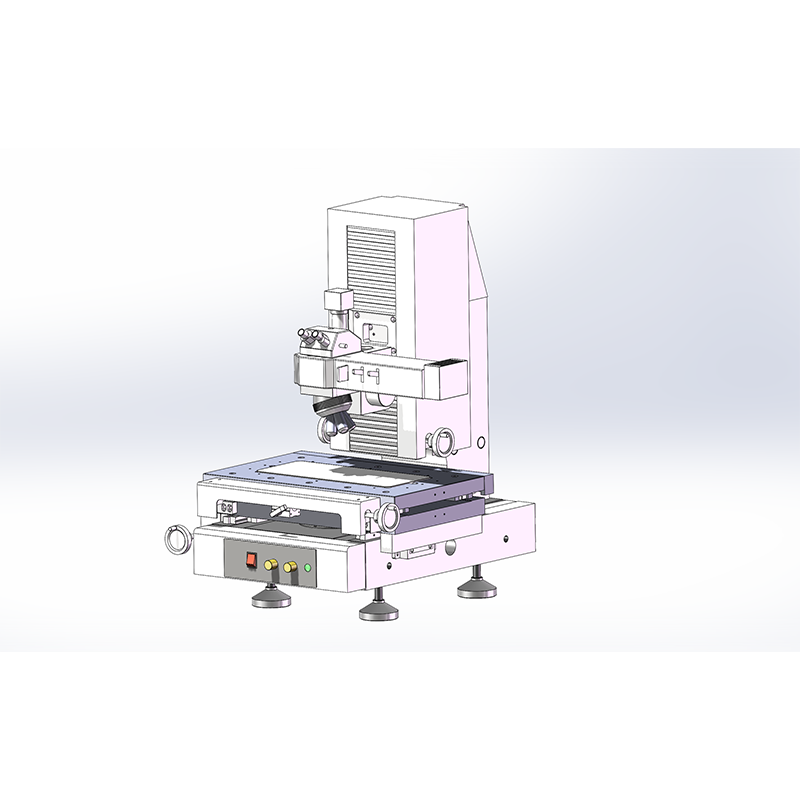

Hot New Products Manual Optical Measuring Machine - Manual vision measuring machine with metallographic systems – Handing

Hot New Products Manual Optical Measuring Machine - Manual vision measuring machine with metallographic systems – Handing Detail:

|

Model |

HD-212MS |

|

X/Y/Z measurement stroke |

200×100×200mm |

|

Z axis stroke |

Effective space: 150mm, working distance: 45mm |

|

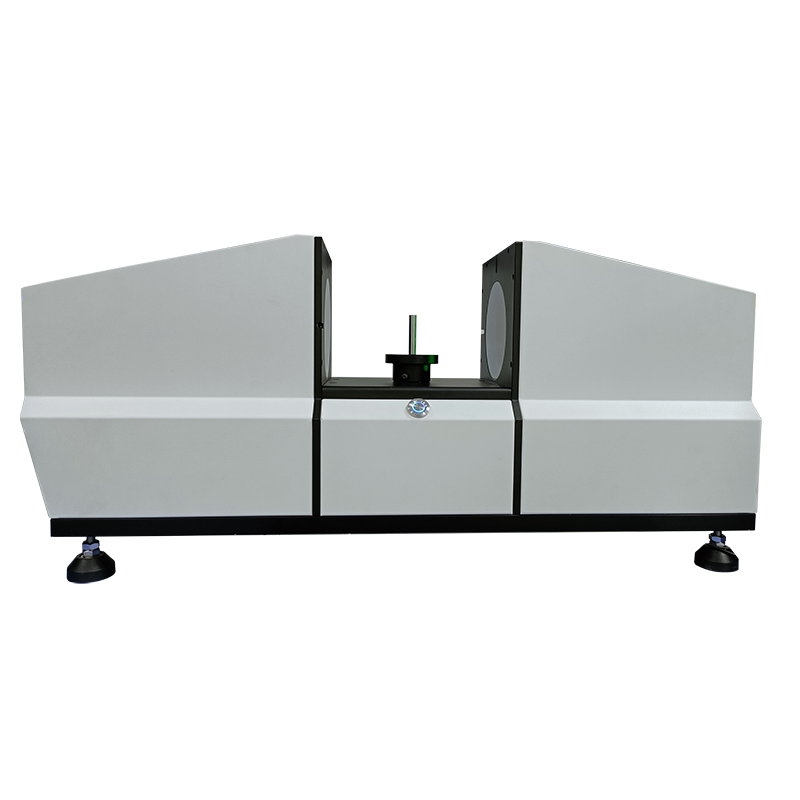

XY axis platform |

X/Y mobile platform:Grade 00 cyan marble; Z axis column: cyan marble |

|

Machine base |

Grade 00 cyan marble |

|

Size of glass countertop |

250×150mm |

|

Size of marble countertop |

400×260mm |

|

Bearing capacity of glass countertop |

15kg |

|

Transmission type |

X/Y/Z axis: Linear guides and polished rods |

|

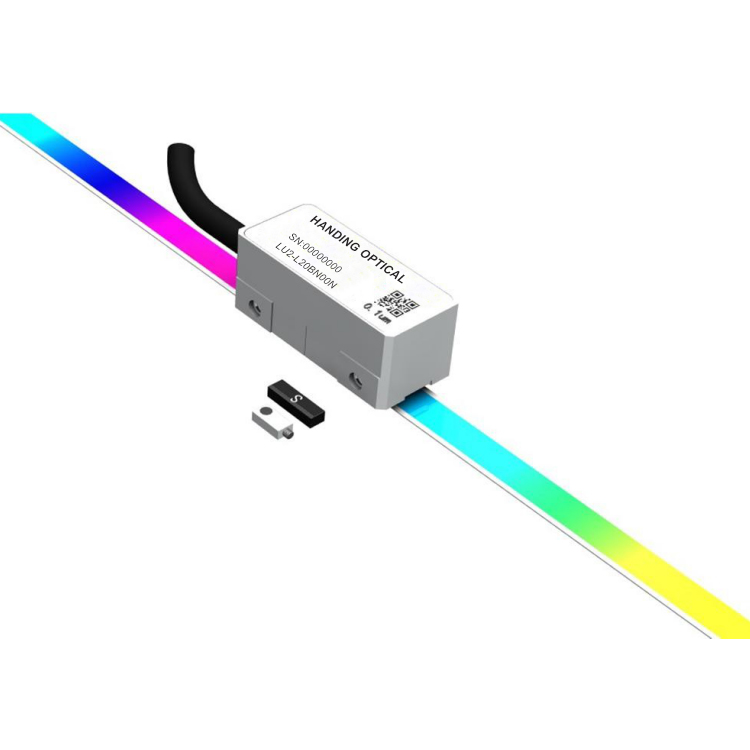

Optical scale |

0.001mm |

|

X/Y linear measurement accuracy (μm) |

≤3+L/200 |

|

Repetition accuracy (μm) |

≤3 |

|

Camera |

HD Industrial Camera |

|

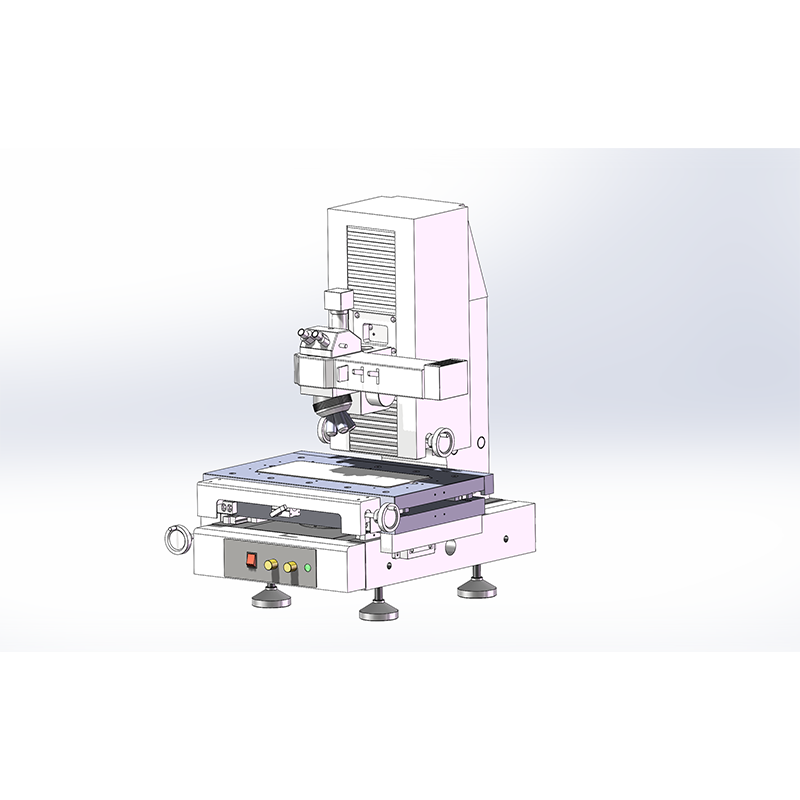

Observation method |

Brightfield, oblique illumination, polarized light, DIC, transmitted light |

|

Optical system |

Infinity Chromatic Aberration Optical System Metallurgical objective lens 5X/10X/20X/50X/100X optional Image magnification 200X-2000X |

|

Eyepieces |

PL10X/22 Plan High Eyepoint Eyepieces |

|

Objectives |

LMPL infinity long working distance metallographic objective |

|

Viewing Tube |

30° hinged trinocular, binocular: trinocular = 100:0 or 50:50 |

|

Converter |

5-Hole Tilt Converter with DIC Slot |

|

The body of the metallographic system |

Coaxial coarse and fine adjustment, coarse adjustment stroke 33mm, fine adjustment accuracy 0.001mm, With coarse adjustment mechanism upper limit and elastic adjustment device, Built-in 90-240V wide voltage transformer, dual power output. |

|

Reflective lighting systems |

With variable market diaphragm and aperture diaphragm and color filter slot and polarizer slot, With oblique lighting switch lever, single 5W high-power white LED and continuously adjustable brightness |

|

Projection lighting systems |

With variable market diaphragm, aperture diaphragm, color filter slot and polarizer slot, With oblique lighting switch lever, single 5W high-power white LED and continuously adjustable brightness. |

|

Overall dimension(L*W*H) |

670×470×950mm |

|

Weight |

150kg |

|

Computer |

Intel i5+8g+512g |

|

Display |

Philips 24 inches |

|

Warranty |

1 year warranty for the whole machine |

|

Switching power supply |

Mingwei MW 12V/24V |

1.With manual focus, the magnification can be switched continuously.

2.Complete geometric measurement (multi-point measurement for points, lines, circles, arcs, rectangles, grooves, measurement accuracy improvement, etc.).

3.The automatic edge finding function of image and a series of powerful image measurement tools simplify the measurement process and make the measurement easier and more efficient.

4.Support powerful measurement, convenient and quick pixel construction function, users can construct points, lines, circles, arcs, rectangles, grooves, distances, intersections, angles, midpoints, midlines, verticals, parallels and widths by simply clicking on graphics.

5.The measured pixels can be translated, copied, rotated, arrayed, mirrored, and used for other functions. The time for programming can be shortened in case of a large number of measurements.

6.The image data of measurement history can be saved as a SIF file. In order to avoid differences in the measurement results of different users at different times, the position and method of each measurement for different batches of objects shall be the same.

7.The report files can be output according to your own format, and the measurement data of the same workpiece can be classified and saved according to the measurement time.

8.Pixels with measurement failure or out of tolerance can be separately re-measured.

9.The diversified coordinate system setting methods, including the coordinate translation and rotation, redefinition of a new coordinate system, modification of coordinate origin and coordinate alignment, make the measurement more convenient.

10.The shape and position tolerance, tolerance output and discrimination function can be set, which can alarm the unqualified size in the form of color, label, etc., allowing users to judge data more quickly.

11.With 3D view and visual port switching function of working platform.

12.Images can be output as JPEG file.

13.The pixel label function allows users to find measurement pixels more quickly and conveniently when measuring a large number of pixels.

14.The batch pixel processing can select the required pixels and quickly execute the program teaching, history resetting, pixels fitting, data exporting and other functions.

15.Diversified display modes: Language switching, metric/inch unit switching (mm/inch), angle conversion (degrees/minutes/seconds), setting of decimal point of displayed numbers, coordinate system switching, etc.

① Temperature and humidity

Temperature: 20-25℃, optimal temperature: 22℃; relative humidity: 50%-60%, optimal relative humidity: 55%; Maximum temperature change rate in the machine room: 10℃/h; It is recommended to use a humidifier in dry area, and use a dehumidifier in humid area.

② Heat calculation in the workshop

·Keep the machine system in the workshop operating in the optimum temperature and humidity, and the total indoor heat dissipation must be calculated, including the total heat dissipation of indoor equipment and instruments (lights and general lighting can be ignored)

·Heat dissipation of human body: 600BTY/h/person

·Heat dissipation of workshop: 5/m2

·Instrument placement space (L*W*H): 3M ╳ 3M ╳ 2.5M

③ Dust content of air

The machine room shall be kept clean, and the impurities greater than 0.5MLXPOV in the air shall not exceed 45000 per cubic foot. If there is too much dust in the air, it is easy to cause resource read and write errors and damage to the disk or read-write heads in the disk drive.

④ Vibration degree of machine room

The vibration degree of machine room shall not exceed 0.5T. Machines that vibrate in the machine room shall not be placed together, because the vibration will loosen the mechanical parts, joints and contact parts of the host panel, resulting in abnormal operation of the machine.

Which countries and regions have your products been exported to?

At present, many customers in South Korea, Thailand, Singapore, Malaysia, Israel, Vietnam, Mexico, and Taiwan Province of China are using our products.

What are the working hours of your company?

Domestic business working hours: 8:30 am to 17:30 pm;

International business working hours: all day.

Which customer audits have your company passed?

BYD, Pioneer Intelligence, LG, Samsung, TCL, Huawei and other companies are our customers.

Are your products traceable? If so, how is it implemented?

Each of our equipment has the following information when it leaves the factory: production number, production date, inspector and other traceability information.

1.With manual focus, the magnification can be switched continuously.

2.Complete geometric measurement (multi-point measurement for points, lines, circles, arcs, rectangles, grooves, measurement accuracy improvement, etc.).

3.The automatic edge finding function of image and a series of powerful image measurement tools simplify the measurement process and make the measurement easier and more efficient.

4.Support powerful measurement, convenient and quick pixel construction function, users can construct points, lines, circles, arcs, rectangles, grooves, distances, intersections, angles, midpoints, midlines, verticals, parallels and widths by simply clicking on graphics.

5.The measured pixels can be translated, copied, rotated, arrayed, mirrored, and used for other functions. The time for programming can be shortened in case of a large number of measurements.

6.The image data of measurement history can be saved as a SIF file. In order to avoid differences in the measurement results of different users at different times, the position and method of each measurement for different batches of objects shall be the same.

7.The report files can be output according to your own format, and the measurement data of the same workpiece can be classified and saved according to the measurement time.

8.Pixels with measurement failure or out of tolerance can be separately re-measured.

9.The diversified coordinate system setting methods, including the coordinate translation and rotation, redefinition of a new coordinate system, modification of coordinate origin and coordinate alignment, make the measurement more convenient.

10.The shape and position tolerance, tolerance output and discrimination function can be set, which can alarm the unqualified size in the form of color, label, etc., allowing users to judge data more quickly.

11.With 3D view and visual port switching function of working platform.

12.Images can be output as JPEG file.

13.The pixel label function allows users to find measurement pixels more quickly and conveniently when measuring a large number of pixels.

14.The batch pixel processing can select the required pixels and quickly execute the program teaching, history resetting, pixels fitting, data exporting and other functions.

15.Diversified display modes: Language switching, metric/inch unit switching (mm/inch), angle conversion (degrees/minutes/seconds), setting of decimal point of displayed numbers, coordinate system switching, etc.

Product detail pictures:

Related Product Guide:

Our personnel are generally in the spirit of continuous improvement and excellence, and together with the outstanding high quality merchandise, favorable price tag and fantastic after-sales solutions, we try to gain every single customer's rely on for Hot New Products Manual Optical Measuring Machine - Manual vision measuring machine with metallographic systems – Handing , The product will supply to all over the world, such as: Sri Lanka, Czech republic, Germany, For more than ten years experience in this filed, our company has gained high reputation from home and abroad. So we welcome friends from all over the world to come and contact us, not only for business, but also for friendship.

We have been looking for a professional and responsible supplier, and now we find it.

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

-

Top