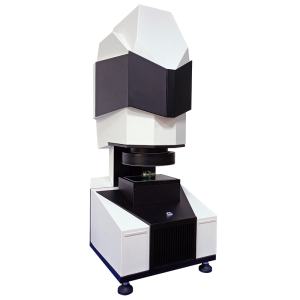

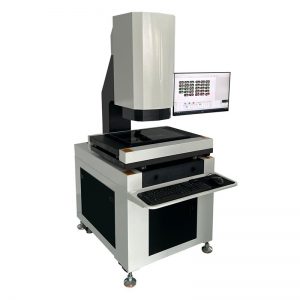

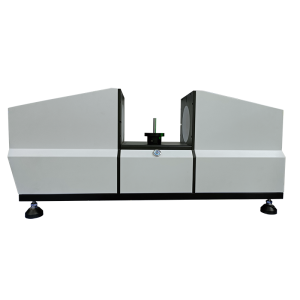

Horizontal and vertical integrated instant vision measuring machine

| Model | HD-9685VH | |

| Image Sensor | 20 million pixel CMOS*2 | |

| light receiving lens | Bi-telecentric lens | |

| Vertical lighting system | White LED ring spotlight with surface | |

| Horizontal lighting system | Telecentric Parallel Epi-Light | |

| Object view | vertical | 90*60mm |

| horizontal | 80*50mm | |

| Repeatability | ±2um | |

| measurement accuracy | ±3um | |

| Software | FMES V2.0 | |

| Turntable | diameter | φ110mm |

| load | <3kg | |

| range of rotation | 0.2-2 revolutions per second | |

| Vertical lens lift range | 50mm,automatic | |

| Power supply | AC 220V/50Hz | |

| Working environment | Temperature:10~35℃,humidity:30~80% | |

| Equipment power | 300W | |

| Monitor | Philips 27" | |

| Computer host | intel i7+16G+1TB | |

| Measurement functions of the software | Points, Lines, Circles, Arcs, Angles, Distances, Parallel Distances, Circles with Multiple Points, Lines with Multiple Points, Arcs with Multiple Segments, R Angles, Box Circles, Identify Points, Point Clouds, Single or Multiple Quick Measurement.Intersect, Parallel, Bisect, Perpendicular, Tangent, Highest Point, Lowest Point, Caliper, Center Point, Center Line, Vertex Line,Straightness, roundness, symmetry, perpendicularity, position, parallelism,Position tolerance, geometric tolerance, dimensional tolerance. | |

| Software marking function | Alignment, vertical level, angle, radius, diameter, area, perimeter dimension, thread pitch diameter, batch dimension, automatic judgment NG/OK | |

| Reporting function | SPC Analysis Report, (CPK.CA.PPK.CP.PP) Value, Process Capability Analysis, X Control Chart, R Control Chart | |

| Report output format | Word、 Excel 、TXT、PDF | |

We always develop corresponding optical measuring equipment in response to market customers' requirements for measuring the precise dimensions of products that are constantly updated.

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

Write your message here and send it to us

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

-

Top