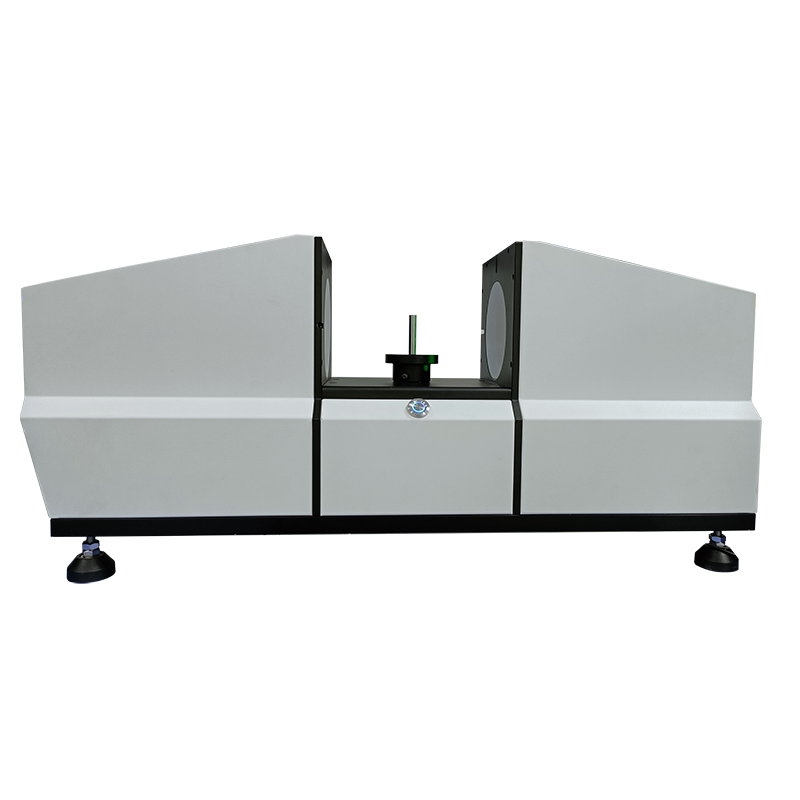

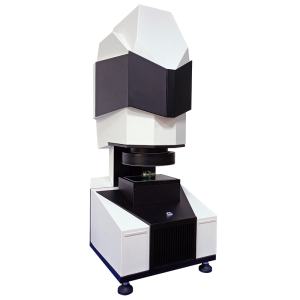

Discover the ultimate image dimension measurement system.

We usually perform being a tangible workforce making sure that we will give you the most beneficial excellent plus the finest selling price for Discover the ultimate image dimension measurement system., With a wide range, top quality, acceptable costs and stylish designs, our solutions are extensively used within this industries and other industries.

We usually perform being a tangible workforce making sure that we will give you the most beneficial excellent plus the finest selling price for Image Dimension Measurement System, We always insist on the management tenet of “Quality is first, Technology is basis, Honesty and Innovation”.We’ve been able to develop new products and solutions continuously to a higher level to satisfy different needs of customers.

| Model |

HD-100H |

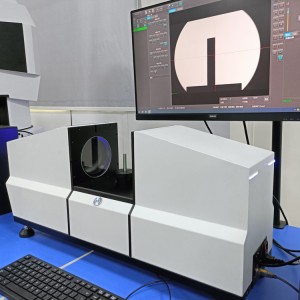

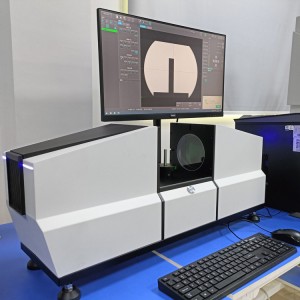

| CCD | 20 Million pixel industrial camera |

| Lens | Ultra-clear bi-telecentric lens |

| Light source system | Telecentric parallel contour light and ring-shaped surface light. |

| Z-axis movement mode |

3KG |

| Load-bearing capacity |

100×75mm |

| Visual field |

±2μm |

| Repeatability accuracy |

±5μm |

| Measurement accuracy |

IVM-2.0 |

| Measurement software | It can measure single or multiple products at the same time |

| Measurement mode |

1-3S/100pieces |

| Measurement speed |

AC220V/50Hz,300W |

| Power supply |

Temperature: 22℃±3℃ Humidity: 50~70% Vibration: <0.002mm/s, <15Hz |

| Operating environment |

35KG |

| Weight |

12months |

How long does your normal product delivery time take?

Assembly time: Open optical encoders are in stock, 3 days for manual machines, 5 days for automatic machines, 25-30 days for bridge-type machines.

Are your products traceable? If so, how is it implemented?

Each of our equipment has the following information when it leaves the factory: production number, production date, inspector and other traceability information.

What is your production process?

Receiving orders – purchasing materials – full inspection of incoming materials – mechanical assembly – performance testing – shipping.

What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment. The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

What is the product warranty?

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone’s satisfaction.

Discover the ultimate image dimension measurement system. Receive accurate results instantly. Enhance your buying decisions with this powerful tool.

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

-

Top